Welcome to consult and negotiate

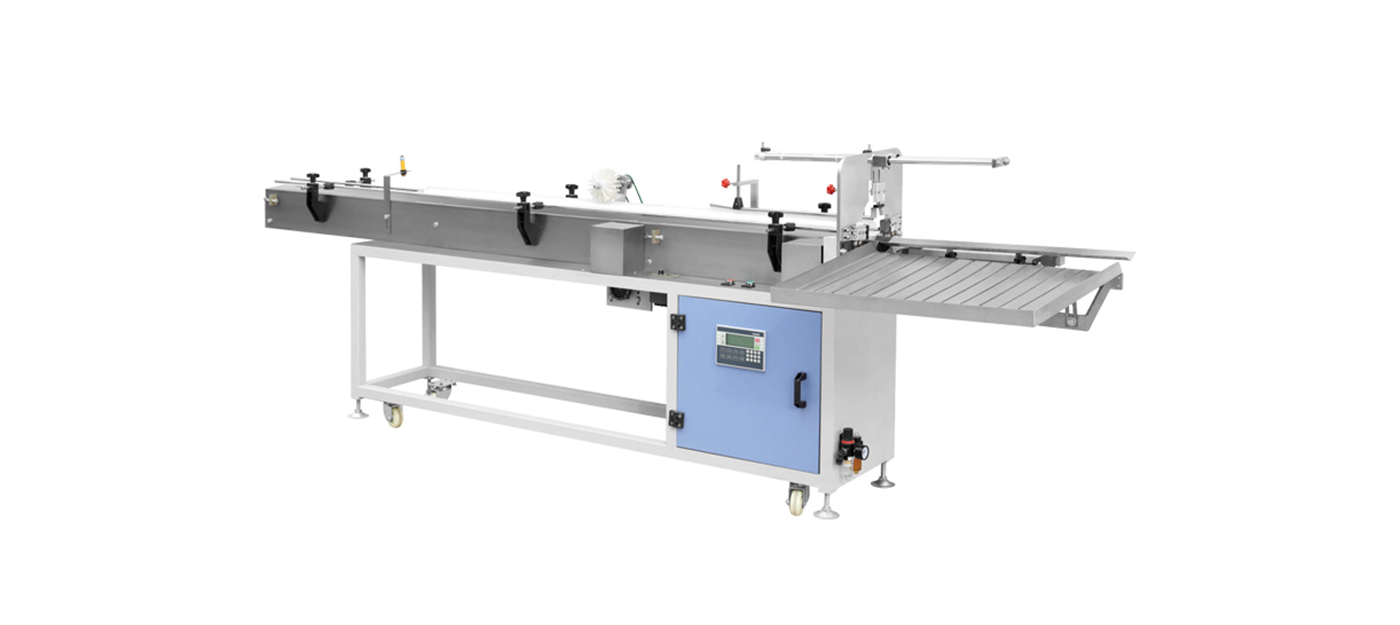

RM-2RH Cup Making Machine

Description

RM-2RH This two-station in-die cutting positive and negative pressure thermoforming machine is an advanced equipment for producing large-height products such as disposable cold drink cups, containers and bowls. The machine is equipped with in-mold hardware cutting and online palletizing system, which can realize automatic stacking after air forming. Its high-efficiency production capacity and automatic stacking function can effectively improve production efficiency, reduce labor costs, and adapt to large-scale production needs.

Machine Parameters

| Molding area | Clamping force | Running speed | Sheet thickness | Forming height | Forming pressure | Materials |

| Max. Mould Dimensions |

Clamping Force | Dry Cycle Speed | Max. Sheet Thickness |

Max.Foming Height |

Max.Air Pressure |

Suitable Material |

| 820x620mm | 85T | 48/cycle | 2.8mm | 180mm | 8 Bar | PP, PS, PET, CPET, OPS, PLA |

Features

Two-station design

The machine adopts a two-station in-mold cutting design, which can perform in-mold cutting and forming operations at the same time to improve production efficiency.

Positive and Negative Pressure Thermoforming

Combining positive and negative pressure thermoforming process can produce attractive looking, strong and durable disposable cold drink cups, boxes and bowls and other products.

In-mold metal knife die cutting

Equipped with an in-mold hardware knife die cutting system, which can achieve precise in-mold cutting and ensure that the edges of the product are neat and burr-free.

Online palletizing system

The equipment is equipped with an online palletizing system, which can automatically stack finished products to improve production efficiency and reduce manual operations.

Application

RM-2RH This machine has a wide range of application fields, especially for food packaging industry and catering service industry. Disposable cold drink cups, boxes, bowls and other products are widely used in fast food restaurants, coffee shops, beverage shops and other places, meeting consumers' needs for hygiene and convenience.